Polyurethane belts for conveying applications

The unique chemical and mechanical characteristics of our timing belts together with the possibility of a wide variety of backings indifferent materials make our timing belts ideal for all conveying applications where synchronization is required.

Polyamide fabric backings

The special polyamide fabric backings allow a reduction of the friction coefficient and when applied on teeth, decrease noise in high speed drives.They are very useful in applications with sliding surfaces or product accumulation.

|

|

|

| Tooth facing fabric | Nylon fabric on the belt back | Nylon fabric on tooth facing and on belt back |

Polyurethane film backing (foil)

Among all synthetic materials and rubber compounds, polyurethane is the material which offers the best resistance to abrasion.Polyurethane films of different thickness and different shore hardness, applied on our timing belts, are an ideal solution in many applications in the wood processing, ceramic and glass industry.

|

|

|

Polyurethane foam backings

Polyurethane foams are easily compressible according to the cellular structure of the material. Due to this main characteristic, common applications are:labelling equipment, light and/or fragile materials conveying, glass and paper industry, vacuum conveyors.

|

|

|

| Polyuréthane | Polyuréthane foam |

PVC backings

PVC has a high coefficient of friction and a good resistance to acids.Due to its versatility, it is used in many applications in the paper, glass, ceramic industry, labelling and packing equipment.FDA quality allows the application in food industry processes.

|

|

|

| High coefficient of friction | Good wear resistance, high coefficient of friction | Good wear resistance, high coefficient of friction |

Rubber backing

Many different rubber backings in both synthetic and natural rubber are available.

|

|

|

| Hight coefficient of friction, very good resistance to cut and tear. | Good wear and tear resistance, high coefficient of friction | Truly endless backing which guarantee long belt life.Hight coefficient of friction, very good resistance to cut and tear |

Spéciality

|

|

|

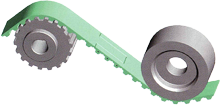

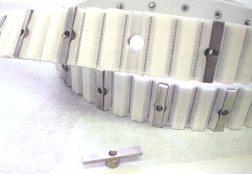

New timing belt EMF - Mechanical Fastening System

Our new EMF - mechanical Fastening system allows in many conveying applications cost savings associated with being able to design equipment arround the installation principle of EMF.

Features

'¢ EMF has no exposed metal parts, therefore no metal contact is made with pulleys, so it runs very quiet. Since there are no exposed metal parts, EMF will not damage conveyed products like competing metal based mechanical fastening alternatives.

'¢ EMF maintains the same minimum pulley requirements as the belt and can operate with back bend idlers.

'¢ It is excellent for belt applications with special backings such as Linatex, Supergrip, PVC, Fishbone, etc.EMF fits snug, which eliminates gaps otherwise seen in competing designs.

'¢ It is suitable for belts with profiles for quick installation, saving time and money.

'¢ EMF installs in seconds, making it the fastest timing belt installation for product conveyance. There is no need for time-consuming field welding.

'¢ It is simple to install and requires no cumbersome or expensive field welding equipment.

'¢ It can be custom designed according to the application strength needed. EMF can reach the same strength as the traditional welding

'¢ It is available on all pitches, making it a "must have" for all of your customer's conveying applications.

Polyurethane belts with profiles

It is possible to attach a wilde range of profiles on our polyurethane belts for conveying, handling and positioning applications.

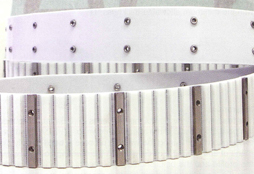

EFT - Mechanical Profile System

EFT is a new mechanical profile application system specially designed for attaching cleats that cannot be welded onto polyurethane timing belts.

It is offered in zinc-coated or stainless steel teeth with either our embedded tooth or total tooth design. The total tooth design replaces the entire tooth of the belt and has two securing threaded holes. The embedded tooth design eliminates metal-to-metal contact, making this a more quiet solution.

Features

'¢ A self-centering effect on profile positioning, which makes it more precise than welded profiles.

'¢ Can handle much higher loads than welded profiles, making it a strong solutions

'¢ It is the precise solution eliminating any welded profile positioning tolerances. The profile positioning tolerance for EFT mirrors our polyurethane timing belt tooth pitch tolerance.

'¢ It is versatile, allowing customers to attach cleats made of steel, stainless steel, plastic, urethane, wood, or virtually any other material.

'¢ It is flexible, allowing customers to reposition cleats for regularly schedule application changes.

'¢ It is economical because customers can replace worn profiles without replacing the entire belt.

'¢ It is available in any of the following pitches: AT10, ATK10, AT20, H, XH.

PROFILES

Our company offers a wide range of profiles. Some configurations are shown in the following pages.

For all other shapes needed, please contact our technical office..